Technical Parameters

Contact us

General Glue Dispensing Machine

Current location:HOME>TDT-400 Automatic Flood Light Glass Cover Sealing Machine

TDT-400 Automatic Flood Light Glass Cover Sealing Machine

Principle Description

Assembled flood light body is placed in the glue dispensing work station. After being glued as the programmed track, the light body moves to glass cover sealing work station. The glass cover is automatically put on the light

- Product introduction

- Technical Parameters

- Video display

Principle Description

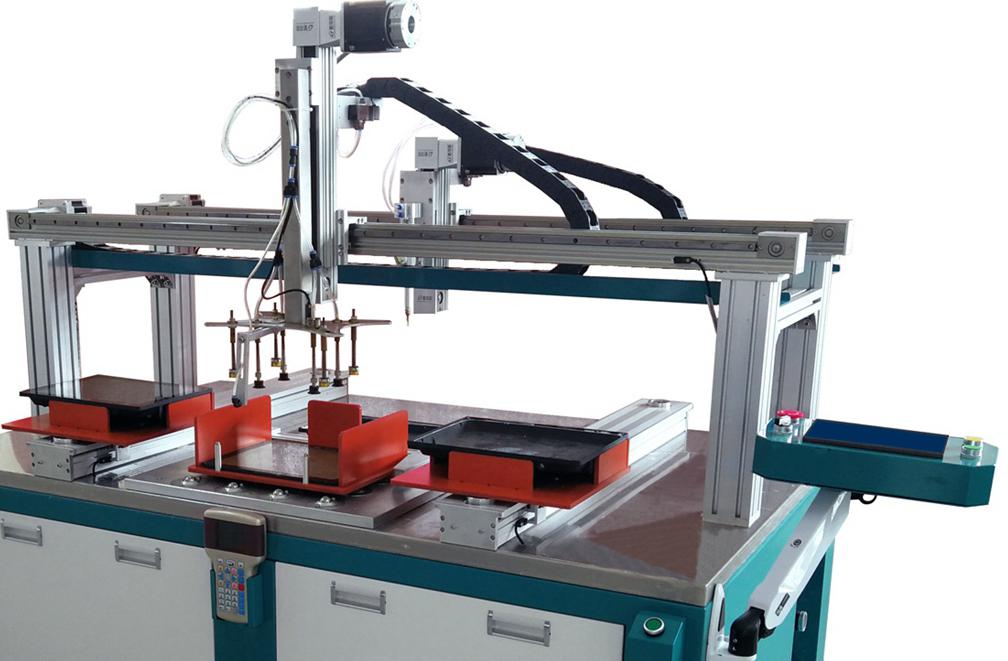

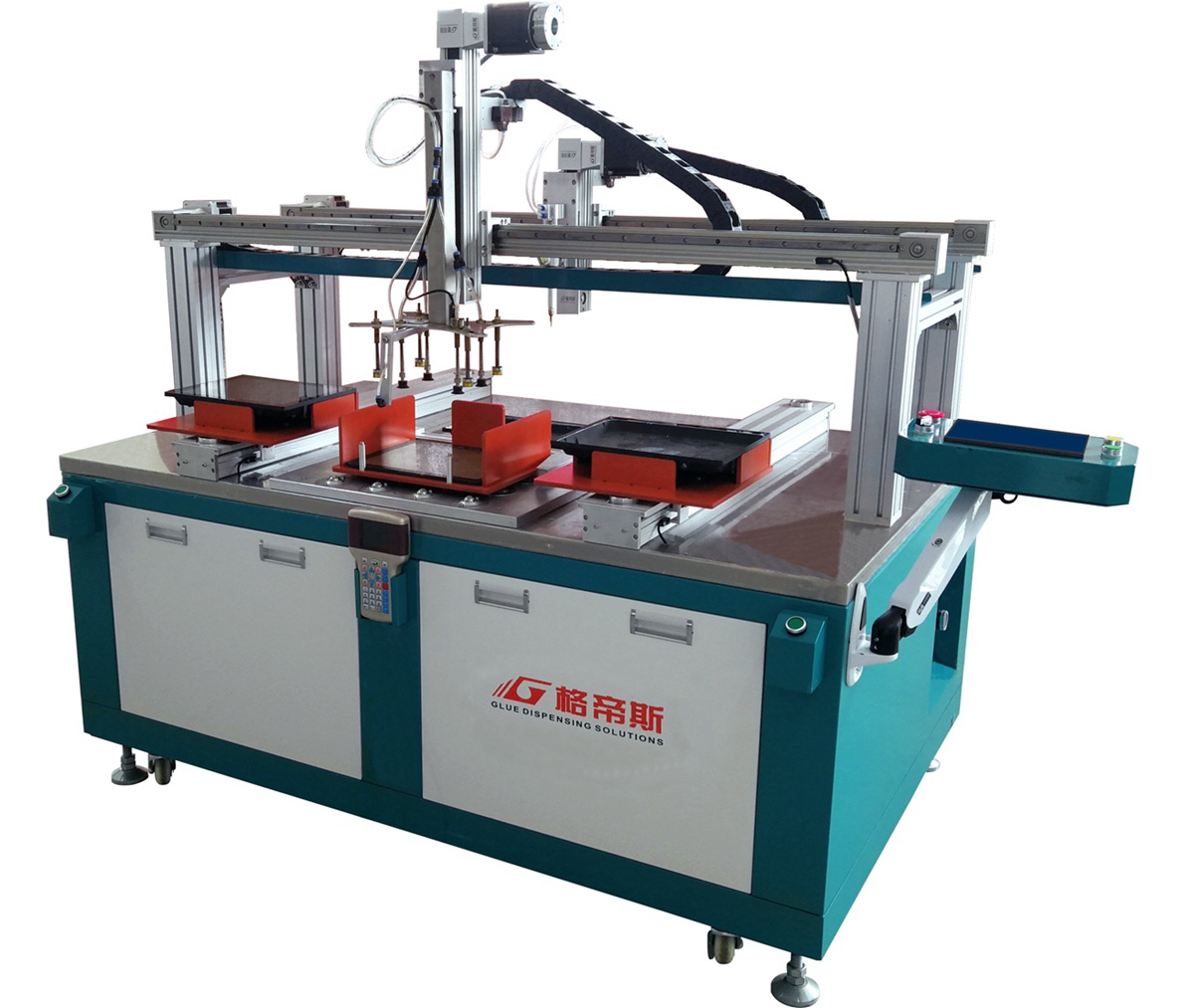

u Assembled flood light body is placed in the glue dispensing work station. After being glued as the programmed track, the light body moves to glass cover sealing work station. The glass cover is automatically put on the light body and then the assembled one is moved away manually. Two work stations run in cycle.

Machine Features

u Two glue dispensing work stations and glass sealing work station are controlled by two independent movement system. They work simultaneously, which can save waiting time and improve the efficiency of sealing glass for flood light. The capacity can reach 200pcs/h;

u The availabe glue dispensing range is 400*400mm, suitable for most flood light design;

u The fixture for glass cover can hold up to 20pcs, and it can be reloaded while machine is running;

u Unique patented design to avoid the situation that two glass cover stick together tightly due to electrostatic or humidity while sucking up the glass cover;

u Teaching pendant and touch screen control, easy to learn and operate;

Suitable Glue: 2600ml package single component glue

Applications: LED flood light and products which need gluing and glass sealing integration